- Empty cart.

- Continue Shopping

MS® PVDF Hydrophobic Membrane Filter(Disc Membrane) ** While Stock Last **

RM1,193.00

Delivery date subjected to stock availability.

Kindly contact us to confirm stock available before placing the order.

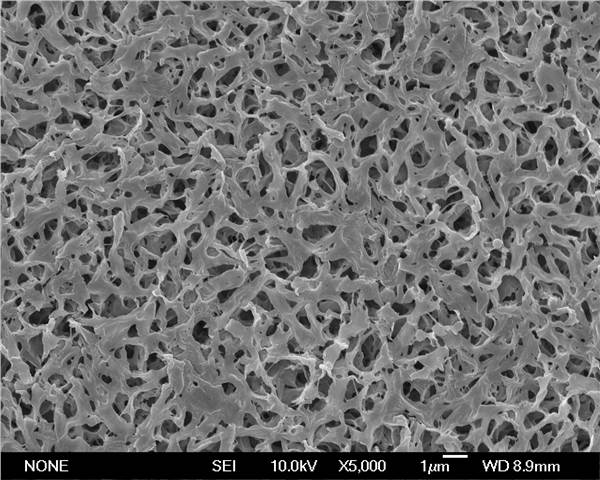

MS® PVDF membrane filter, particularly micro-porous membrane, can be prepared to exhibit high efficiency for particle removal. PVDF membrane has a low critical surface energy and conventional, hydrophobic, micro-porous PVDF membranes will not be wet by aqueous fluids.

MS Membrane stack consists of reinforced-type PVDF membrane. It can ensure wet air and other gas pass through smoothly, even when the differential pressure is very low. It holds the opposite capability against PVDF hydrophilic membrane.

Features

- Wide chemical compatibility

- Excellent mechanical properties

- High temperature capabilities and excellent aging resistance

- Easy processing by extrusion, injection, compression, blow molding, solution process

- Physiologically harmless and approved for contact with food products -Low extractable levels

Applications

- Chemical Process Industry (pipes and fittings, pumps, valves, …)

- Off shore oil industry (multi layer structures for oil and gas…)

- High purity fluid transportation

- Wire and cables (communication cable jacket in the USA, …)

- Plumbing

- Lithium batteries

Technical Parameter

| Membrane Material | Pore Size(µm) | Average Bubble Point(Mpa) | Flow Rate(25°C) Δp = 0.07 Mpa (mL/min/cm2) | Thickness(um) |

| PVDF(Hydrophobic) | 0.22 | 0.12-0.15( Alcohol ) | 8-12 | 120-140 |

| 0.45 | 0.06-0.1( Alcohol ) | 30-45 | ||

| PVDF(Hydrophilic) | 0.22 | 0.36-0.42(Water) | 8-15 | 120-140 |

| 0.45 | 0.18-0.24(Water) | 35-60 |

Available Options

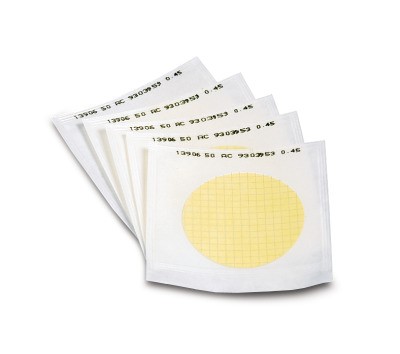

| Thumbnail | SKU | Description | Stock | Price | Quantity | |

|---|---|---|---|---|---|---|

| F-MFPVDF047022 | PVDF MEMBRANE FILTER 0.22UM X 47MM | RM1,193.00 | |||

| F-MFPVDF047045 | Hydrophobic PVDF Membrane Filter, Pore: 0.45(μm), Diameter: 47(mm) | RM1,193.00 |