- Empty cart.

- Continue Shopping

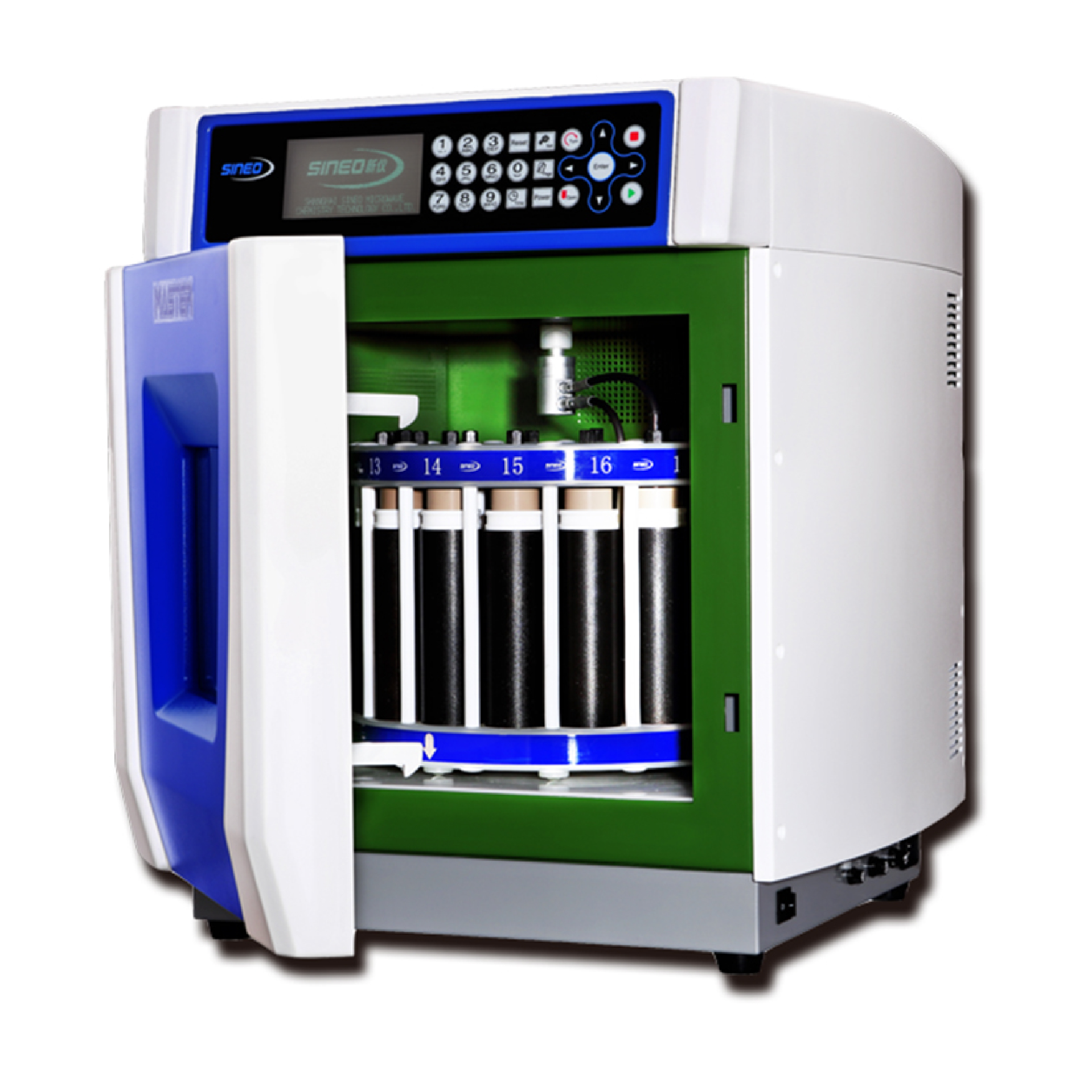

Laboratory Multifunctional Microwave Chemistry Reaction Workstation (UWave-2000 )

This product is currently out of stock and unavailable.

Laboratory Multifunctional Microwave Chemistry Reaction Workstation (UWave-2000 )

UWave-2000 Multifunctional Microwave Chemistry Reaction Workstation is the upgrade of Sineo’s best seller UWave-1000, with Sineo’s 20 years of microwave chemical experience andscientific achievements of many scientists. It integrates the atmospheric pressure and pressurized reactions, microwave heating, ultrasonic wave and ultraviolet irradiation and other functions, and provides the workstation with flexibility and reliability for the microwave chemical research. UWave-2000 hasa intelligent operating system, and 7-inch touch screen control is simple and friendly; It realizes the multi-energy and multifunctional free combination and collocation with the modular design, giving inspiration to your experiment; Itcan conduct the 2000ml open vessel reaction and 500ml pressurized reactionmaximally, thus can help researchers conduct the mass production experiment.Regardless of organic extraction, pharmaceutical research, protein chemistry,novel material science, research of the graphene, polymer synthesis and manyother fields, UWave-2000 will provides various imaginations and feasibility ofthe microwave chemical research.

Unique advantage:

Good Innovation: Integrate the atmospheric pressure and pressurized reaction, microwave, ultrasonic wave and ultraviolet irradiation and other functions, giving full flexiblility;

High reproducibility: Microwave automatic frequency conversion control, dual temperature control technology, and piezoelectric crystal pressure can ensure the accurate record and representation of each reaction;

Severe safety: Pressurized mode, intelligent safety pressure control system, real-time over pressure alarm and active pressure relief, outer vessel with composite fiber and other safety protection measures at the highest level;

Friendly operation: 7-inch color LCD touch screen, intelligent software,safe and remote control, and reaction process video graphy facility;

Reliable durability: Multi-layer Teflon coating 316L stainless steel chamber and durable reaction container material ensure that all kinds of chemical reactions proceed smoothly;

Reliable experience: 20 years’ industry experience, ISO and CE certificated, and national leading number of users;

Three energy sources – microwave, ultrasonic and ultraviolet irradiation can be free combined and work together,and software control them timing on and off, achieving the synergistic effectby multi energies. UWave-2000 adopts immersion ultrasonic launcher, with an adjustable scope of ultrasound power: 0 – 800W, frequency of 28KHZ, and automatic frequency sweeping and frequency locking; With two sets of ultravioletsource (standard UV lamp power is 300W, dominant wavelength is 365nm, while optional UV lamp power is 100W, and dominant wavelength is 254nm), it can conduct selective photochemical research. UWave-2000 is equipped with multiple reaction vessels, 50-2000ml glass flasks can meet the routine use, and optional multi-standards quartz reaction flasks can meet photochemical reaction under the ultraviolet radiation.

UWave-2000 can conduct the high-pressuresealed reaction, and is equipped with three kinds sealed reaction vessels -100ml, 200ml and 500ml, solving the amplification process from the laboratoryresearch to the production verification. The sealed reaction vessel can meetthe long-term reaction process under 230°C and 2Mpa, greatly expanding the temperature pressure conditions ofatmospheric pressure reaction. Under pressurized mode, UWave-2000 hasintelligent safety pressure control system for realizing the real-timeoverpressure alarm and active pressure relief, and external vessel with composite fiber and high strength metal frame ensure the safe and smooth reaction.

High-precision dual-channel infrared temperature sensor and platinum resistor temperature sensor can switch automatically, with infrared temperature measurement range of 0 – 900°C (standard configuration of 300°C), platinum resistor temperature measurement range of 0 – 250°C and precision of ±1°C. The pressurized reaction is equipped with the patentedpiezo-electric crystal (pressure control range of 0 – 5MPa, precision of ±0.01MPa), realizing the pressure monitoring of reaction process and ensuring the safe and comfortable experiment. The same system can conduct themicrowave atmospheric pressure and pressurized reaction and the software canjudge the type of the reaction vessel automatically for preventing the wrong operation.

UWave-2000 is equipped with mechanical and magnetic stirring device. Digital constant speed mechanical stirring isespecially applicable to the high viscosity liquid reaction, with rotation speed of 30 – 1600r/min. It can realize real-time speed regulation and displaysthe rotation speed (±10r/grade),with torque of 300 N.m. It can stir clockwise or anti clockwise, with mechanical stirring rod material of PEEK or quartz. Built-in magnetic stirring rotationspeed is 0~800r/min, speed program is adjustable and of real-time display.

UWave-2000 is equipped with intelligent control software. It can transmit the reaction parameters and curves byconnecting with the computer, and can record each reaction process and curve unlimitedly; It can conduct real-time control or change the reaction parametersof the host through the computer, realizing user’s programmed on or off ofthree energy sources – microwave, ultrasonic and UV radiation. 7-inch color LCDtouch screen can make accurate setting and real-time display of various reaction parameters and curves, and conduct the real-time display of reactioncolor image. The chamber is equipped with color recording system, which canrealize real-time display of reaction image through the color LCD screen, andcan output the image signal for facilitating user’s recording or external connection.

It has large volume 316L stainless steel industrial oven chamber. The extra-large oven chamber with high-strengthanticorrosive coating treatment can meet the maximum 2000 ml atmosphericpressure reaction and; Oven chamber is equipped with high-speed fan, with airrate of 3m3/min. 3-gear speed change will be made automatically according tothe reaction situation; It is equipped with reflux condensation, dropping liquid, water diversion and other devices, and is equipped with inert shielding gas access pipe; This product passes IS09001:2008 and EU safety CE certification.

Technical parameters

| Power supply | 220-240VAC 50/60Hz 9A |

| Microwave source | 2450MHz, 0-1000W, continuous, non-pulse and automatically adjustable along with the temperature program, PID technology |

| Microwave oven chamber | Large volume, 316L stainless steel chamber, applied with multi-layer anticorrosive PFA Teflon spray inside and outside |

| Temperature measuring and control system | Dual-channel temperature detection DTD technology, switchable control. Infrared temperature sensor range 0~900℃, precision ±1℃, PT-100 resistor temperature sensor range 0~250℃, precision ±1℃ |

| Pressure measuring and control system | Piezoelectric crystal pressure sensor, pressure control range: 0~5MPa (750psl), precision of ±0.01 MPa |

| Working temperature | standard configuration instrument’s maximum operating temperature is 300℃ and the maximum theoretical operating temperature is 900℃(peculiar configuration). The standard maximum working temperature of high-pressure reaction is 230℃. |

| Working pressure | The standard maximum working pressure of high-pressure reaction is 2 MPa, with constant pressure control valve, and constant pressure value of 2 MPa. |

| UV light source system | It can be equipped with two sets of ultraviolet light, with UV power of 300W and the dominant wavelength of 365nm (standard); UV power of 100W and the dominant wavelength of 254nm (optional) |

| Ultrasonic system | Immersion ultrasonic launcher, with adjustable scope of ultrasound power: 0 – 800W, frequency of 28KHZ, and automatic frequency sweeping and frequency locking |

| Stirring system | Digital constant speed mechanical stirring, with rotation speed of 30 – 1600r/min. It can realize real-time speed regulation and displays ±10r/grade, with torque of 300 N.m. It can stir clockwise or anticlockwise; Built-in magnetic stirring rotation speed of 0~800r/min, speed program is adjustable and of real-time display. |

| Software system | With Windows software and 7-inch color LCD touch screen, it can make accurate setting and real-time display of various parameters and curves, and can transmit the reaction parameters and curves by connecting with the computer, and record and realize the control or change of each reaction process unlimitedly; |

| Video system | Color image recording system is equipped, which can realize real-time display of reaction process through 7-inch color LCD screen. And it can realize the transmission and recording by connecting the computer. |

| Interface | USB2.0 Serial port |

| Exhaust system | Oven chamber is equipped with high-speed hot blast fan, with blast capacity of 3m3/min. 3-gear speed change will be made automatically according to the reaction situation |

| Atmospheric pressure reaction vessel | Standard 50~1000ml high borosilicate glass reaction vessel and condensation, reflux, charging accessories, optional 2000ml high borosilicate glass vessel, optional 50~1000ml quartz reaction vessel |

| High pressure reaction vessel | 100ml, 200ml and 500ml TFM high pressure digestion inner vessel, aerospace composite fiber explosion-proof outer vessel, high-strength alloy frame |

| Working environment temperature/humidity | 0~40℃/15~80% RH |

| Physical size of whole machine | 500*625*580 (Width×depth×height), 48kg |