- Empty cart.

- Continue Shopping

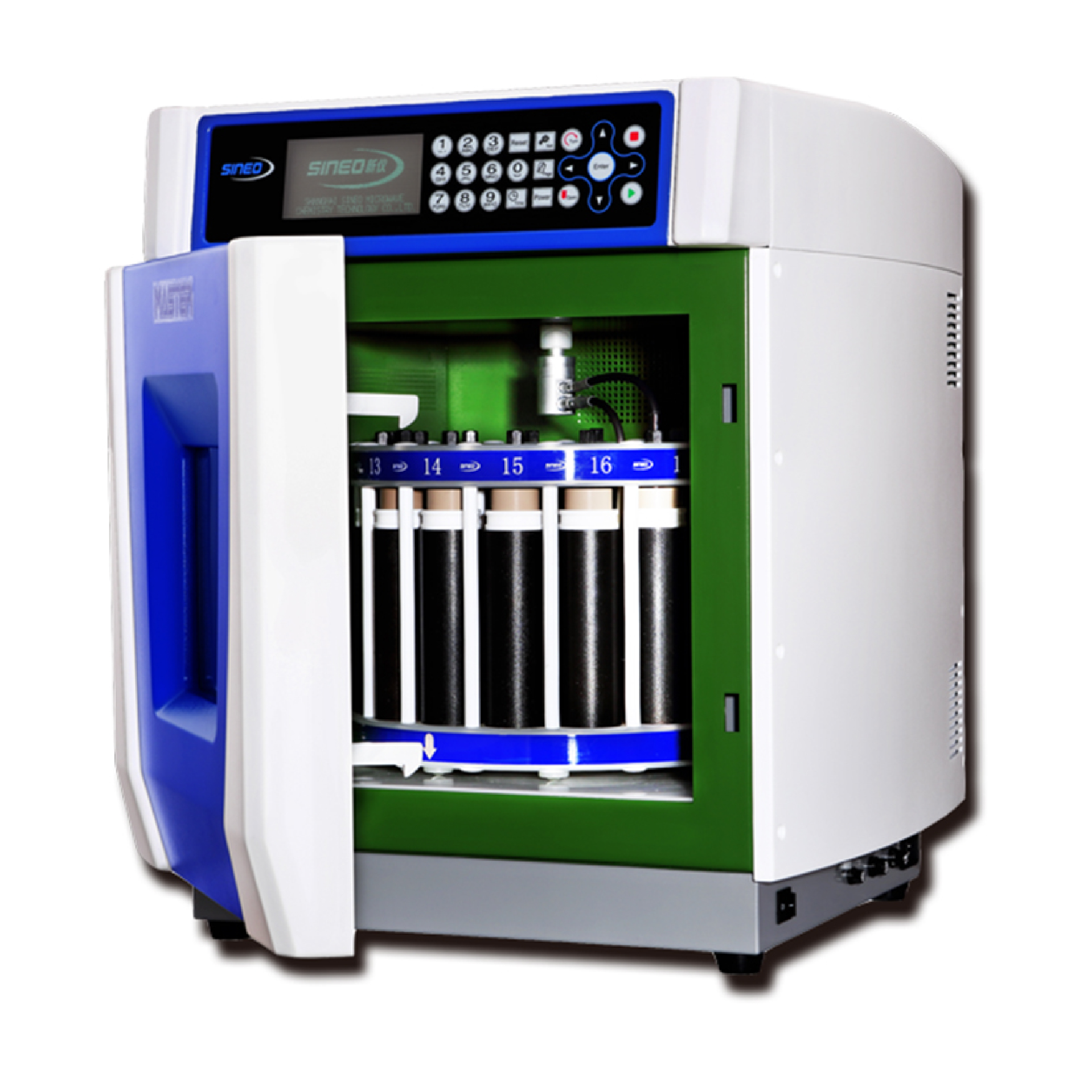

Laboratory Ultra High Throughput Closed Microwave Digestion/Extraction Workstation

This product is currently out of stock and unavailable.

MASTER

Ultra High Throughput Closed Microwave Digestion/Extraction Workstation

- More than 20 years of experience in microwave;

- Leader in number of users nationally of 9000+ units;

- 6-year supplier of Administration of Quality Supervision, Inspection and Quarantine of P.R.C;

- 100 vessel throughput, NO.1 in the world;

- 4 times BCEIA gold award of China Association for Instrumental Analysis;

- Various choices of vessel configurations, throughput of: 16 and 40 vessels; volume of: 15ml, 30ml, 50ml, 70ml, 100ml, 200ml and 500ml;

- Free lifetime warranty to the core components-magnetron of the Microwave Digestion System;

With the most advance technology and material of Shanghai Sineo Microwave Chemistry Technology Co., LTD., MASTER serial ultrahigh throughput microwave digestion/extraction workstation was launched in 2012. MASETER cavity is versatile for 16-vessel independent frame-type high pressure digestion rotor, 18-vessel carousel integrated ultrahigh pressure digestion rotor, 40/100-vessel ultrahigh throughput carousel rotor and 16-200ml-vessel carousel large capacity rotor etc., meets different experiment application requirements. Other core technologies including airplane Xtra Fiber digestion outer vessel, quantitative Safety Bolt patented design, UTH-Caro design of high throughput carousel, unique piezoelectric crystal pressure measuring technology and Uni-Turn technology of one direction continuous rotation of digestion rotor in chamber, et.al.

With the popularity of analytical instruments, e,g, Mass Spectrometer, there are increasing demands of rapid and efficient microwave sample preparation instrument with high productivity. However, the present high throughput microwave digestion products on the market that mostly adopt the spring structure are those which may bear low pressure, be easy to be leaked, and may not be heated evenly and operated easily. The MASTER closed microwave digestion system is developed by aiming at coping all the above mentioned problems, and the followings may show its unique characteristics of the innovative technologies:

1. High-strength alloy carousel: higher pressure and better digestion performance.

The high throughput vessel, since being connected by the high tensile alloy draw bar, may withstand great pressure (≥10000Kg). Each digestion vessel may receive great supports from the vessel frame on its top and bottom and it may not be deformed or leaked under the pressure of ≤4MPa and temperature of ≤250℃. (However, those similar products made by other venders generally may bear the temperature of 210℃ maximally.)

2. UTH-Caro design makes the carousel stir the microwave, guarantee samples digested evenly

The high throughput vessel frame may homogenize the microwave field inside the chamber with the turning and stirring of frame vessel; therefore, up to 100 high throughput vessels may be heated evenly in the microwave field.

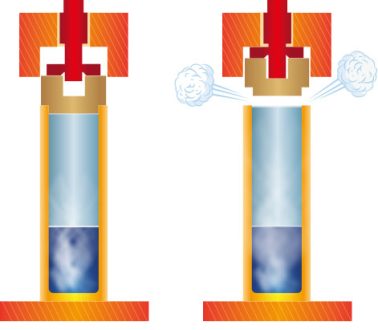

3. Safety Bolt: safer, more accuracy in result and higher recycling rate.

Quantified Safety Bolt design, ensures samples be closed completely and triggers a quantified pressure relief while over pressure; Safety Bolt unit, instead of safety membrane and other consumables, ensure the digestion vessel be sealed completely under normal working conditions, which avoids the loss of volatile elements and incomplete digestion. And only when the pressure is too high and may constitute a danger, the Safety Bolt will automatically blow out vertically and the cover auto-up to release the pressure, achieving quantified vertical blast pressure-relief to guarantee its well operation. Under normal operation, the Safety Bolt requires no replacement. In addition, it is easy for venting to open the cover after completion of digestion. (However, those similar products on the market may bear low pressure and temperature, and since the cover is not made of metal, it may not recover after deformation; consequently, it may be not flexible anymore and be useless as it loses its sealing function after several times of recovering. This is why the samples inside the digestion vessel are reduced or dried and it has low recovery rate.)

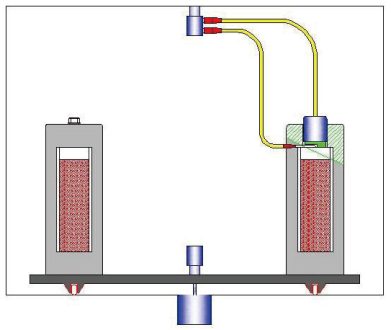

4. Uni-Turn technology, increased homogeneity and reliability.

The whole set of digestion vessels was designed to rotate continuously in one direction, it breaks conventions of<360° back and forth rotation, avoiding uneven heating on vessels and reducing impact on turntable motor to extend service life. The temperature and pressure cables are short, that they are free from twisting in running and can be disassembled easily.

5. 15 minutes fast cooling

Because of the high thermal conductivity of composite Xtra Fiber outer vessel and the efficient exhaust system, it only needs 15 minutes that the temperature cools from 200 ℃ to 60 ℃, greatly accelerates handling speed.

6. Easy operation with innovative tools

The various convenient operation tools may lessen the working burden of operators and increase the preparation efficiency. Let’s take the flexible trolley as an example. Such device may help the experiment personnel to place the high throughput rotary table with fully loaded samples (weighing 15-20kg) in the chamber and take it out easily. In this manner, the operator may not be required to contact the high-temperature and high-pressure digestion vessel directly and will not be injured by acid mist, perfectly ensuring the safety of the operation. The electric tool with fixed moment to close and open the digestion vessel may make the operation of high throughput digestion vessel rapid, simple and fulfilled.

General technical features:

1. Explosion-proof outer vessel made of composite Xtra Fiber, better than those similar products on the market.

The composite Xtra Fiber material is light, thin, and having better hardness (better than metal) and good rigidity. Moreover, its pressure resistance and corrosion resistance performances are much better than PEEK (Poly-Ether-Ether-Ketone) outer vessel. SINEO applies painted PFA processes, improves the corrosion-proof capacity by packing the composite fibers totally. Moreover, the high tensile invincible composite material may withstand pressure of 10000psi and temperature of 500-600℃.

- Advanced and reliable pressure measuring technology by piezoelectric crystal.

At present, the air-pipe is generally applied to transmit, measure and control the pressure inside the vessel for most venders. The air-pipe has apparent demerit that is too long, usually 400-600 mm in length. Hence, the digestion turntable shall rotate back and forth in 360 degrees to avoid the air-pipe being twisted. Besides, the samples in master vessel may be polluted easily, and it may not withstand high pressure to prevent breaking the air pipe. Therefore, after years of research and development, SINEO acquires the pressure measuring technology by piezoelectric crystal, reliable and durable. Such technology may measure and control the pressure under 12 MPa. The measuring and control cable is quite short, only 120-140 mm, therefore, there will be no twisting, sealing joint or leakage. Such technology allows easy operation and its greats merit is the absolute isolation of measuring and controlling component and sample, thus giving no chance to cross contamination. Integrating the technology of synchronous rotation of temperature-pressure device and digestion vessel with the rotary table in one direction and the patented technology of junction box, the turntable plate may rotate towards one directly constantly. The pressure control system is the standard configuration of SINEO’s product, more reliable than units with temperature monitoring only.

- The temperature inside the digestion vessel can be controlled by the combination of precise measure of temperature inside master vessel and IR temperature scanning

The precise measurement and control of temperature inside the master vessel (Pt or optical fiber) combines with the IR temperature scanning, and the computer may identify the master vessel automatically and give the real-time comparison of temperature with standard vessel, more precise and reliable than only IR temperature measuring.

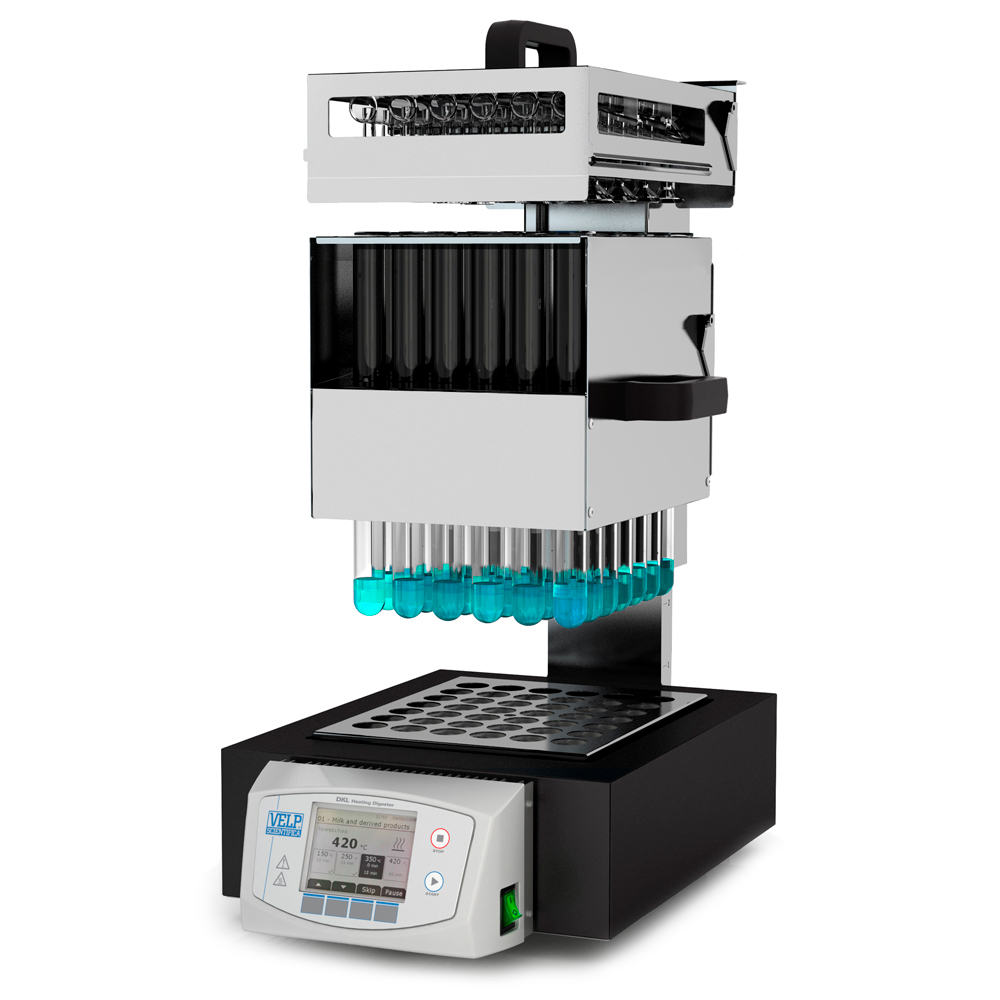

High throughput rotor with optional strong magnetic stirring function specially for extraction or synthesis

Ultra high pressure and high temperature 18-vessel digestion vessel and carousel may work under 6MPa and 260℃, quite suitable for digestion of insoluble samples or closed microwave synthesis under extreme conditions. The strong magnetic stirring function is available for this configuration.- 200ml vessels for large volume sampling.

LV-200 carousel with16-200ml vessels can be reacted simultaneously, and the sample size can reach 1-2 g. Magnetic stirring makes samples be digested faster and thoroughly. The patented design of innovative Safety Bolt can guarantee the safe as well as a completely digestion. The demand of large sampling digestion can be met.

6. Wireless remote visual monitoring system make reaction be clear at a glance.

Innovative remote wireless video monitoring system, makes the digestion process clearly visible. Mobile phones and tablets can realize the observation and monitoring of the reaction, making the operation safer and more convenient.

7. 100-vessel ultrahigh throughput closed microwave digestion vessel and carousel breakthrough products for the industry

To adapt to the rapid development of advanced analytical instrument, the requirement for limit of detection, volume of sample, acid amount and blank interference are decreased, but the amount of samples to be detected are increased. Therefore, small volume, good pressure-bearing capacity and excellent batch processing performance, has become the trend for the development of microwave digestion technology. After releasing the first microwave digestion apparatus with 40 vessels at home, Sineo cooperated with National Research Centre of Geoanalysis and developed MASTER-100. Its unique UTH-Caro design is based on the previous designs and technologies of high throughput products. Such product is well received by the users in geological industry, food industry, sanitary inspection industry and environment industry. The 100-vesssel digestion carousel has 3 volume specifications, 15ml, 30ml and 50ml, and it may be customized according to the specific requirement of the user.

8.One for All

This MASTER series product, may suit different digestion vessel sets and satisfy the requirements of users in different industries and application areas. You may use vessels and rotors in different quantity, temperature/pressure bearing capacities and volume flexibly.

Regular digestion: 16-vessel independent frame type high pressure rotor and 40-vessel ultrahigh throughput carousel; Special Digestion: 18-vessel ultrahigh pressure carousel, 100-vessel ultrahigh throughput carousel and 16-vessel 200ml large volume carousel.

9. Industrial chamber structure, safer operation.

Sturdy and durable industrial-grade chamber design strengthen its impact resistance, and multi-layer chemical resistant coating greatly improves the service life and safety of the system; the pop up cushioning explosion-proof sliding chamber door (Auto-Pop structure) builds a passive safety protection system, and it can disable the microwave power automatically once explosion happens; efficient exhaust system design achieves fast and safe forced air cooling (15 min cooling time from 200℃to 60℃), improving operational efficiency.

10. The complete digestion database with over 1000 methods after safety verification, and has been referred to in several international standards, industrial standards and pharmacopoeia. The high-definition LED display may show the reaction parameters and change of curves in real time on different interfaces, convenient for the modification of the setting of reaction parameters and the saving of digestion solutions as per their types.

11. SINEO has 20 years of experience on the research and development of microwave chemistry instrument. It has ISO 9001:2008 certificate in design of microwave products. Moreover, its products have gotten EU CE safety certificate, and its corporate standards in electromagnetic compatibility, microwave leakage and electric protection go beyond national and international standards. In addition, the company has fully participated in the preparation, issuance and implementation of national standard for Microwave Digestion Device (GB/T 26814-2011)