- Empty cart.

- Continue Shopping

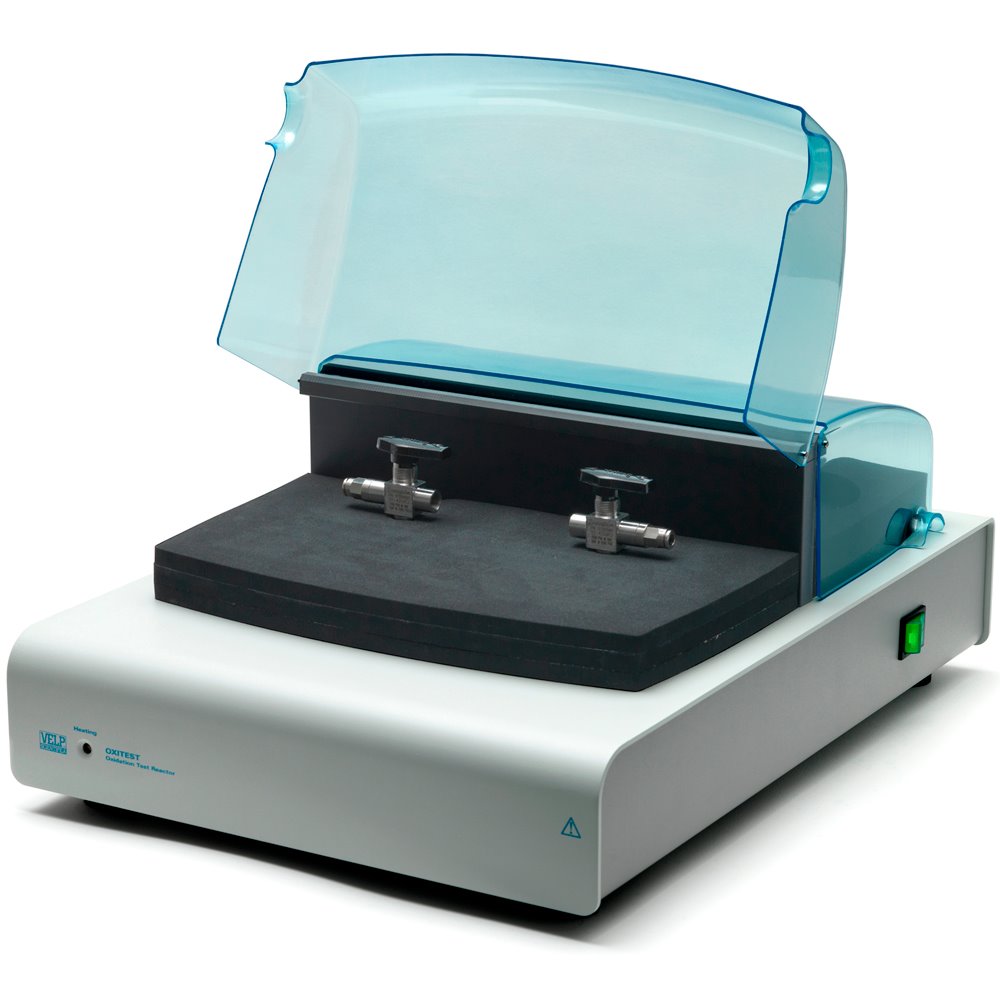

OXITEST Oxidation Stability Reactor

OXITEST Oxidation Stability Reactor

This product is currently out of stock and unavailable.

OXITEST Oxidation Stability Reactor

Innovative accelerated oxidation test for the determination of the oxidation stability of fats on the whole sample according to AOCS Cd-12c-16.

Fats and oils oxidation stability tests for R&D and QC Labs

The oxidation stability tests performed with the OXITEST reactor accelerate the lipid’s oxidation process that in normal conditions can last weeks or months and provide fast, accurate and reliable results for Food & Feed, Cosmetic, Pharma and Petrochemical industries.

The OXITEST provides added value information for Quality Control and Research & Development Labs for:

- Quality control of raw materials and ingredients

- Transportation and effects on goods

- Storage period studies

- Product Development and behavior

- Formula Optimization

- Ingredient and alternative ingredients testing

- Process optimization

- Packaging study and alternative packaging comparison

Representative results testing the whole sample

The OXITEST reactor subjects the sample to a high oxidative stress environment in order to evaluate, in a short period of time, the resistance to fat oxidation:

- Established over-pressure of pure oxygen (6 bar, degree 5.0)

- High constant temperature, 90 °C

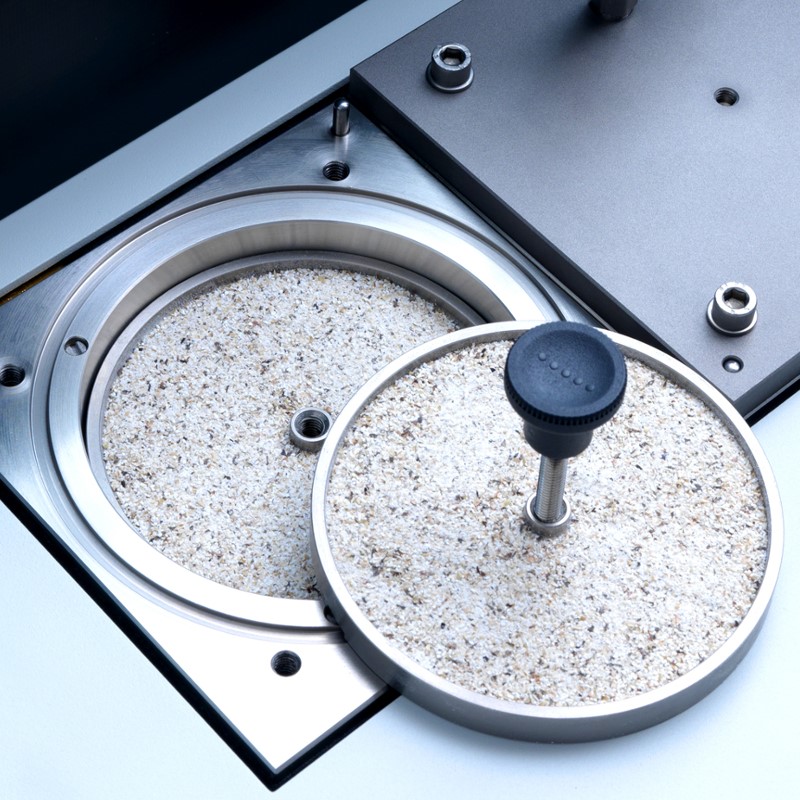

With the OXITEST Method, the stability test is performed directly on the sample as it is solid, liquid or doughy.

The method’s key advantage is that the OXITEST ensures representative results without extensive sample preparation.

Other components of the sample matrix such as chemical oxidants or transition metal can promote oxidation and the use of extracted matter may not be a suitable predictor of stability.

The Induction Period IP

The IP is the time required to reach the starting point of oxidation, corresponding to either a level of detectable rancidity or a sudden change in the rate of oxidation.

The longer the Induction Period, the higher the stability against oxidation over time.

OXISoft™ software powerful and intuitive

The OXITEST is entirely controlled via PC through the intuitive OXISoftTM software which is able to control up to 4 OXITEST simultaneously and independently. The OXISoft™ is quick and easy-to-use, at a glance you always have the program parameters, work conditions and results.

The software comes with multi-lingual support and a pre-installed library of methods related to a wide range of sample types, you can use these, modify them and create your own methods!

Data management, reportiing and archive with the following test types:

- Repeatability test

- Freshness test

- Formulas comparison

- Packaging comparison

- IP during ageing

- Estimated shelf life

Premium titanium parts

The oxidation chambers, sample holders and covers are made of titanium, a premium material guaranteeing:

- High resistance

- Excellent chemical compatibility;

- Easy cleaning

- Cost savings since no disposable consumables are required.

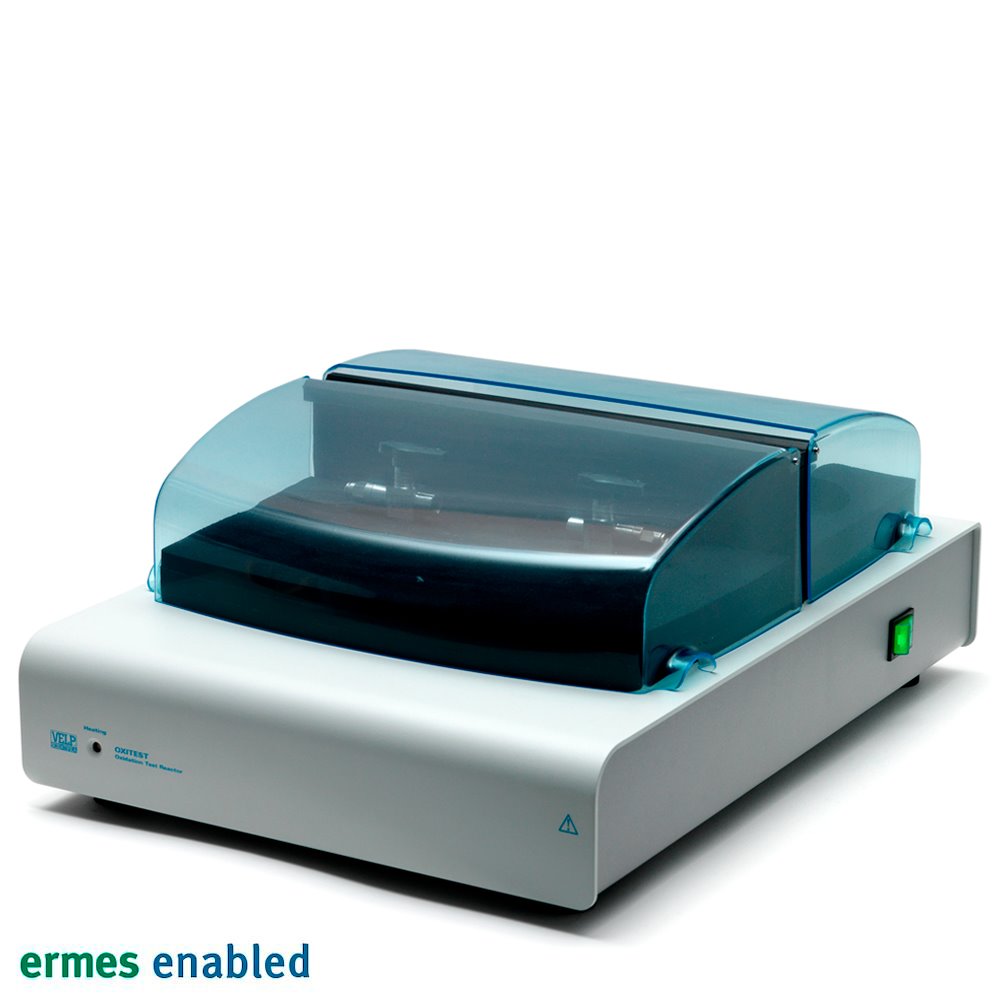

Benefit form cloud-bases services with VELP Ermes

The OXITEST thanks to its connectivity to VELP Ermes allows you to reduce routine operations thanks to the real-time monitoring of your test wherever you are, at any time from PC, smartphone and tablet.

- Real-time monitoring and notification

- Maximum security and data protection

- Anytime access to your data via PC, smartphone and tablet

- Enhanced Service Support (VELP and partners)

- Immediate Software Updates

- Create and share reports, track trend and get useful insights

Included Accessories

- VELP Ermes 1 year Connection

Optional Accessories

TECHNICAL DATA

| NUMBER OF OXIDATION CHAMBERS: | 2 |

| CAPACITY SINGLE CHAMBER: | up to 100 ml |

| PRESSURE RANGE: | 0 – 8 bar |

| TEMPERATURE RANGE: | from room temp. to 120 °C |

| MAX DEVIATION FROM THE SET TEMPERATURE | ≤ 0.5 °C |

| REPRODUCIBILITY OF SET TEMPERATURE | ≤ ± 0.2 °C |

| INTERFACE: | USB |

| CONNECTIVITY | Cloud via LAN or Wi-Fi |

| POWER | 900 W |

| POWER SUPPLY | 115 V / 60 Hz – 230 V / 50-60 Hz |

| WEIGHT: | 16.5 Kg (36.3 lb) |

| DIMENSIONS (WXHXD): | 365x190x485 mm (14.6×7.6×19.4 in) |

| OVERPRESSURE | Safety valve |

| OUT-RANGE TEMPERATURE | Visual alarm |

| DAMAGED PROBE | Visual alarm |